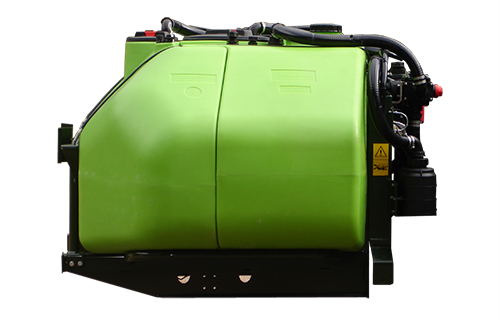

PHYSETER AUXILIARY FRONT TANKS

TECNOSPRA EUROPA presents the PHYSETER auxiliary front tanks with 6 different capacities: 750, 1100, 1200, 1500, 1800 y 2200 l.

Multipurpose tank designed exclusively to be carried on the front of the tractor, capable of performing various tasks in any agricultural cycle.

Auxiliary tank to increase the autonomy of the rear sprayer.

Application of liquid initiators, contact and residual herbicides.

Patented 200501143 (6) and homologated for road traffic.

Patented – patent no. 200501143 (6) – and homologated for road traffic.

COMMON CHARACTERISTICS TO ALL TANKS

UNIT OF LOAD, TRANSFER AND AGITATION WITH HYDRAULIC CENTRIFUGAL PUMP

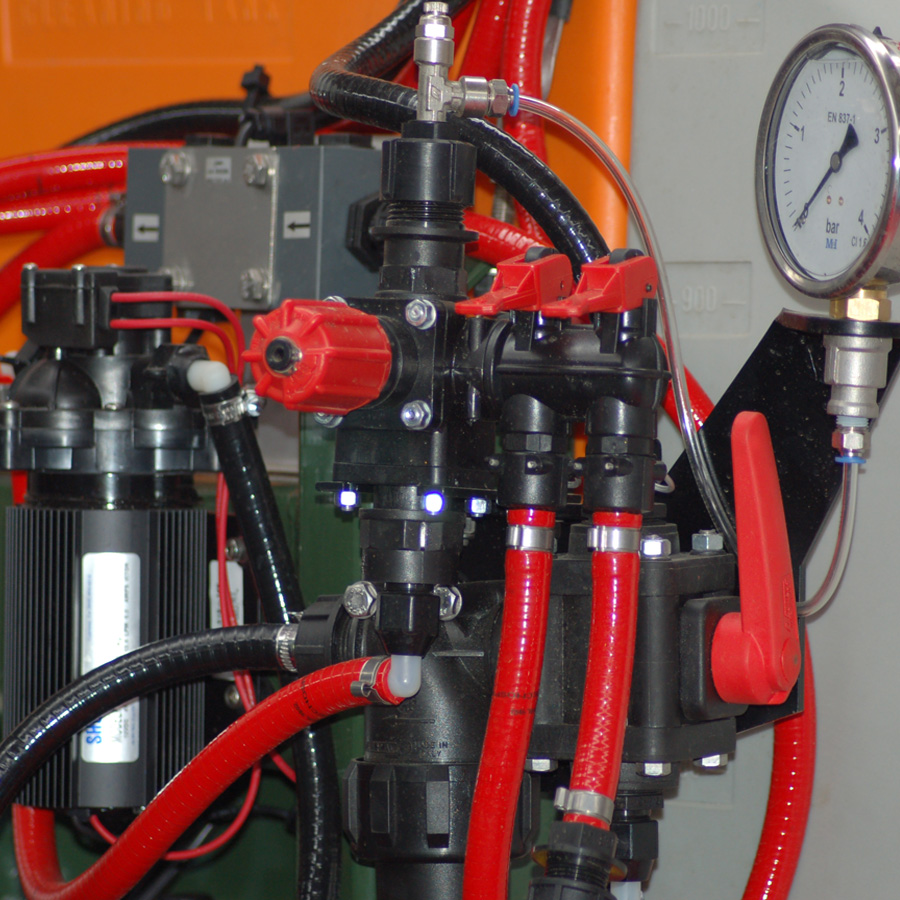

· Hypro self-priming hydraulic centrifugal pump of 750 ltrs, driven by Gerotor hydraulic motor of 40-62 ltrs minute at 180 bars, made of polypropylene with fiberglass, stainless steel and ceramic seal.

· Parker hoses with 3/8 drive and ½ return.

· Parker flow restrictor with safety fixation.

· Check valve to prevent the opposite rotation.

· Possibility of placement in all hydraulic systems, open circuit, closed circuit, and with compensated return.

· Filter of 3 “of aspiration of 35-50 mesh of 600 ltrs. of filtration capacity.

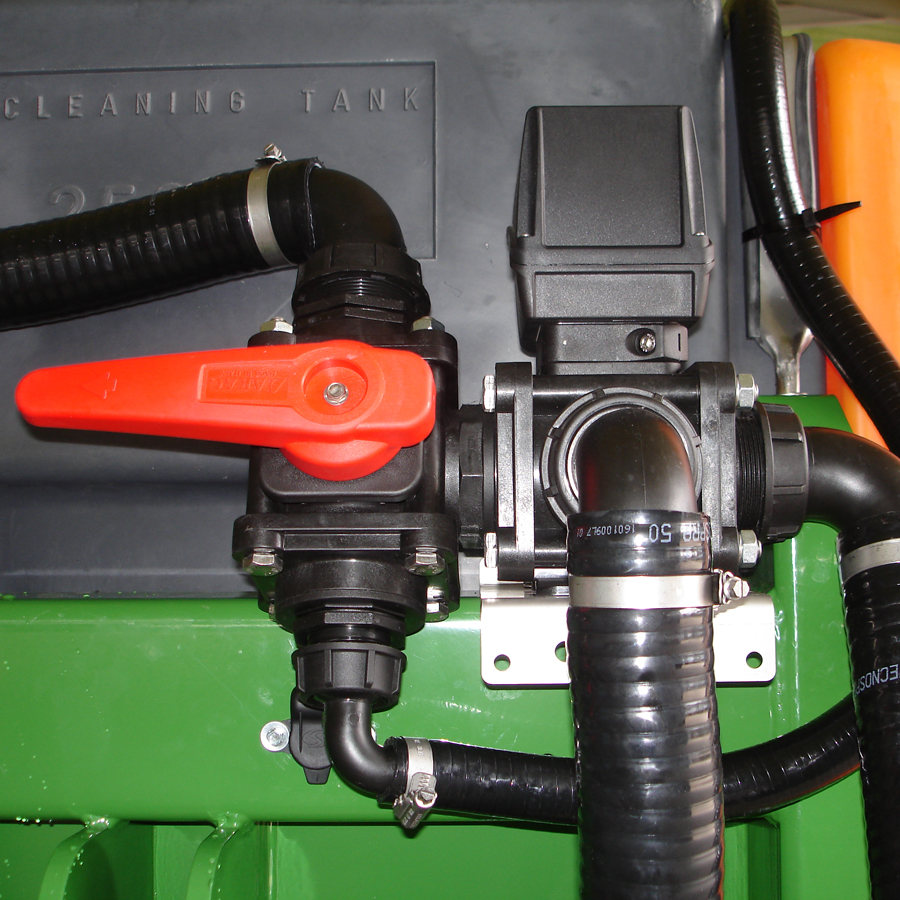

· Five-way valve with 3 “continuous flow braces and 2” outlet in suction and delivery, to perform the functions of loading, agitation and transfer.

· Sealing joints of EPDM.

· 50 Mm hose. with Tecnospra steel anima in both suction and impulsion circuits.

UNIT OF LOAD, TRANSFER AND AGITATION WITH MEMBRANE PUMP

· Desmopan membrane pump driven with Danfoss hydraulic motor.

· Parker hoses with 3/8 drive and ½ return.

· Parker flow restrictor with safety fixation.

· Possibility of placement in all hydraulic systems, open circuit, closed circuit, and with compensated return.

· Filter of 2 “of aspiration of 35-50 mesh of 300 ltrs of filtration capacity.

· 2-way manual distributor with proportional pressure valve.

· 1 ½ three-way solenoid valve to direct the liquid for agitation or transfer to the dep. rear

· Monitor for command lodged in the cabin.

· TECNOSPRA hose of 25 mm. to communicate the front tank with the rear sprayer with 1″ camlock quick couplings.

TRANSFER AND AGITATION ELECTRIC SYSTEM

· Electric pump of constant pressure of 12 v, with capacity of 15 ltrs / m to 2.5 bars manufactured in santoprene, viton and inox. Includes heat sink, pressure switch (2.5 bars) and 90 ° safety thermostat.

· Monitor with two functions – transfer and stirring – to command said pump, on / off switch.

· Mechanical 2-way distributor with proportional pressure valve, with easy-to-read stainless steel gauge, scale 1-2.5 bar, 100 mm.

· Liquid separator for protection of the manometer.

· Venturi nozzle of agitation of 1-2 mm.

· 1 “suction filter and three-way valve 1” braces for circuit washing and 12v pump.

· High quality 13 mm hoses set, possibility to record them with personalized logo and Kamlock quick couplings for perfect operation.

· Endless type flanges and one ear with inner ring in stainless steel.

· Centrifugal pump of 12 v. of stainless steel 316 of 70 ltr / m with ceramic seal and viton.

· Internal suction filter housed in the bottom of the tank.

· Monitor with two functions – transfer and stirring – to command said pump, on / off switch.

· TECNOSPRA hose of 25 mm. to communicate the front tank with the rear sprayer with 1 “camlock quick couplings.